Automation of the different components of a plant can provide the means to address several of challenges.

Project Description: Manufacturing Compliance Console (MCC) is meant to drive compliance at a sterile manufacturing suite. MCC provides interfaces through which “Interventions” can be recorded automatically. MCC is CFR 21 Part 11 compliant and can support server or standalone architecture.

Key accomplishments: No manual recording, no need for getting items required recording in to sterile area. Complete Solution including structural fabrication, CFR 21 Part 11 compliant and Meeting GMP requirements.

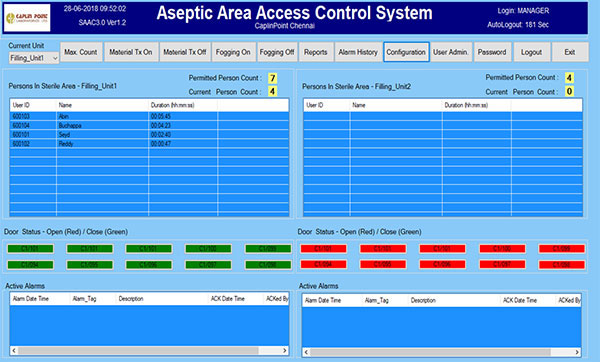

Project Description: SAAC controls the people entry/exit in the sterile areas as per GMP. It can be implemented using industry standard access control components. SAAC provides comprehensive and intuitive reports to aid in the prevention of contamination of sterile areas

Key accomplishments: Automated recording/no manual entries, complete Solution including structural fabrication, CFR 21 Part 11 compliant and meeting GMP requirements.

Project Description: On demand preparation of pre-defined concentrations of solvents, detergents, disinfectants, thereby using full shelf life and avoiding wastage of pre-mixed solutions.

Key accomplishments: Automated recording/no manual entries, Complete Solution including structural fabrication, CFR 21 Part 11 compliant and meeting GMP requirements.

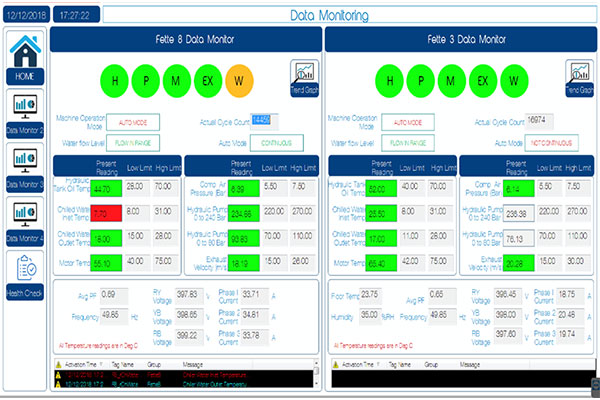

Project Description: Developing a Data Acquisition System which enables Predictive Analysis & Continuous Monitoring of critical operational parameter.

Key accomplishments: Selection of various instruments transmitters, power supplies etc. on existing infrastructure. Data acquisition to PLC & HMI. Storage, Analysis and Visualization of the collected data on Centralized SCADA.

Project Description: Developing a Centralized SCADA System for a Pharma customer which enables operator to Control & Monitor specific plant areas.

Key accomplishments:Generate custom specified reports

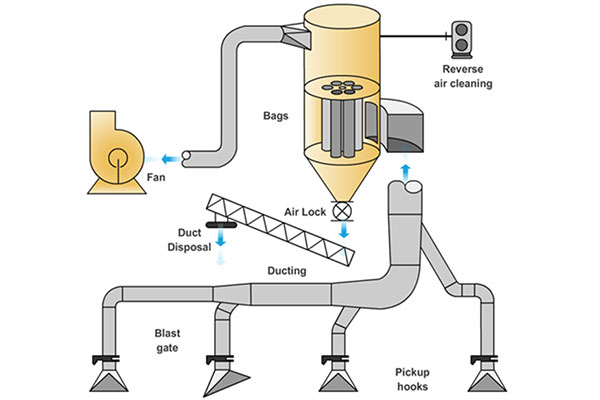

Project Description: Control of purge sequencing, monitor air pressure, integrity of filter cartridge, clogging of filters, dust level in bin, sense filling of pipes for dust collectors in a typical tablet manufacturing plant.

Key accomplishments: Integrating with electrical panel. Animated graphics. Provision for sharing data on central server.